Services

Climate test

Climate test used to help the product survive in any environment until the final operational state. It provide test on hot,cold, humidity, dust and etc environment to prevent the product lack when using in different environment.

Dry Heat Test

- Dry heat testing is the basic test use on development, normally for heat-resistance testing

Temperature Cycle/Thermal Shock Test

- Exposes the products to alternating low and high air temperatures to accelerate failures repeated to simulate normal use.

Temperature/Humidity Test

- Testing the equiment with freezing that will tell you the water that trap in will cause physical damage to your equiment.

Salt Spray Test

- Check corrosion resistance of materials and surface coatings.

Mechanical Stress Test

Used to determine the stability of a equipment or system. The test is operate to observe the result of the equipment such as the strength and the breaking point of equipment.

Pull & Push Test

Button Test

Bending Test

Taber Abrasion Test

RCA Abrasion Test

Izod/Charpy Impact Test

IK Impact Test

Ingress Protection to Enclosure(IP Test)

Hardness Test-Shore A and Shore D

Design verification and validation test

To assure the product meet all the criteria of design specification. and to comfirm the output of software or product can match with the input source. While design validation test is a process that evaluate the software or product can satisfied the customer requirements at the end of the state.

MSL Level

Halt & Hass

Transportation Test

To ensure that the package of the product are good in quality and condition to prevent the unit or equipment lost or damage during transportation. Transport and packaging test are faster and simple,by this test it can reduce cost and all the product are in acceptable condition.

Package Vibration Test

Package Drop Test

Package Compression Test

Electrical safety testing

High Voltage Test

- Applying a significantly higher than normal operating voltage to the device under test.

Leakage Current Test

- Measure the harmful leakage current that flows through or across the surface of the insulation or the dielectric of a capacitor.

Electromagnetic Compability (EMC) Test

To test the acceptably of electrical and electronic equipment in electromagnetic environment. Electromagnetic interference(EMI) may cause unwanted effect and interruption so EMC is to correct all the equipment in common electromagnetic environment.

ESD Test

Surge Test

Burst Test

PQT Test

Pulse Magnetic Field

Power Frequency Magnetic Field

Fire test

Measure the fire protection are meet the minimum performance criteria as it set.

Bend test

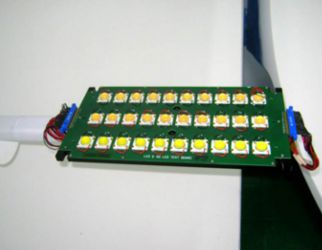

Electrical and photometric measurement of solid state lighting products.

LM 79:2008

To test the material ductility, bend strength, fracture strength and resistance to break.

Total Luminous Flux

- The total visible light energy emitted by a source in all directions, where the luminous flux is the radiant flux multiplied by the human eye’s sensitivity. The unit of measurement for luminous flux is the lumen.

Luminous Intensity Distribution

- A quantity which describes the power of a source or illuminated surface to emit light in a given direction.

Electrical Power

- Rate of Electrical energy transferred in an electric circuit.

Luminous Efficacy (calculation)

- Measurement of the efficiency with which the source provides visible light from electricity.

Colour Characteristics

- Chromaticity - Specification of the quality of colour regardless of its luminance.

- Colour Temperature - The colour temperature of a light source is the temperature of an ideal black-body radiator that radiates light of comparable hue to that of the light source.

- Colour Rendering Index- Effect of an illuminate on the colour appearance of objects by conscious or subconscious comparison with their colour appearance under a reference illuminate.

|

|

|

| INTEGRATING SPHERE (4π MEASUREMENT) |

INTEGRATING SPHERE |

XY HANDLER AUTOMATED TESTER |

LM 80:2008

Lumens maintenance of LED light sources

Ambient conditions and setup

- Case Temperature measured and maintained

- Case Temperature measurement point

- Airflow minimized

- Operating orientation & spacing per manufacturer

Electrical Voltage and Current (AC or DC levels)

- Voltage wave shape (harmonic distortion <3%)

- Current Regulation

Instrumentation

- Constant Current Drivers

- Power Supplies

- Data logger

|

|

|

| INTEGRATING SPHERE (4π MEASUREMENT) |

INTEGRATING SPHERE |

Failure Analysis Test

Failure analysis test use to collect and analysis the data of a failure product. When the product were failed for using, we will do failure analysis test to know the true causes of failure happen and the goal is to correct the failure. By the test, it can improve a product quality, save the cost of wasted and also make the product lives longer by the improvement job.

IV Curve Analysis

X-ray Analysis

C-SAM Analysis

SEM Analysis

EDX Analysis

FESEM Analysis

Cross Section